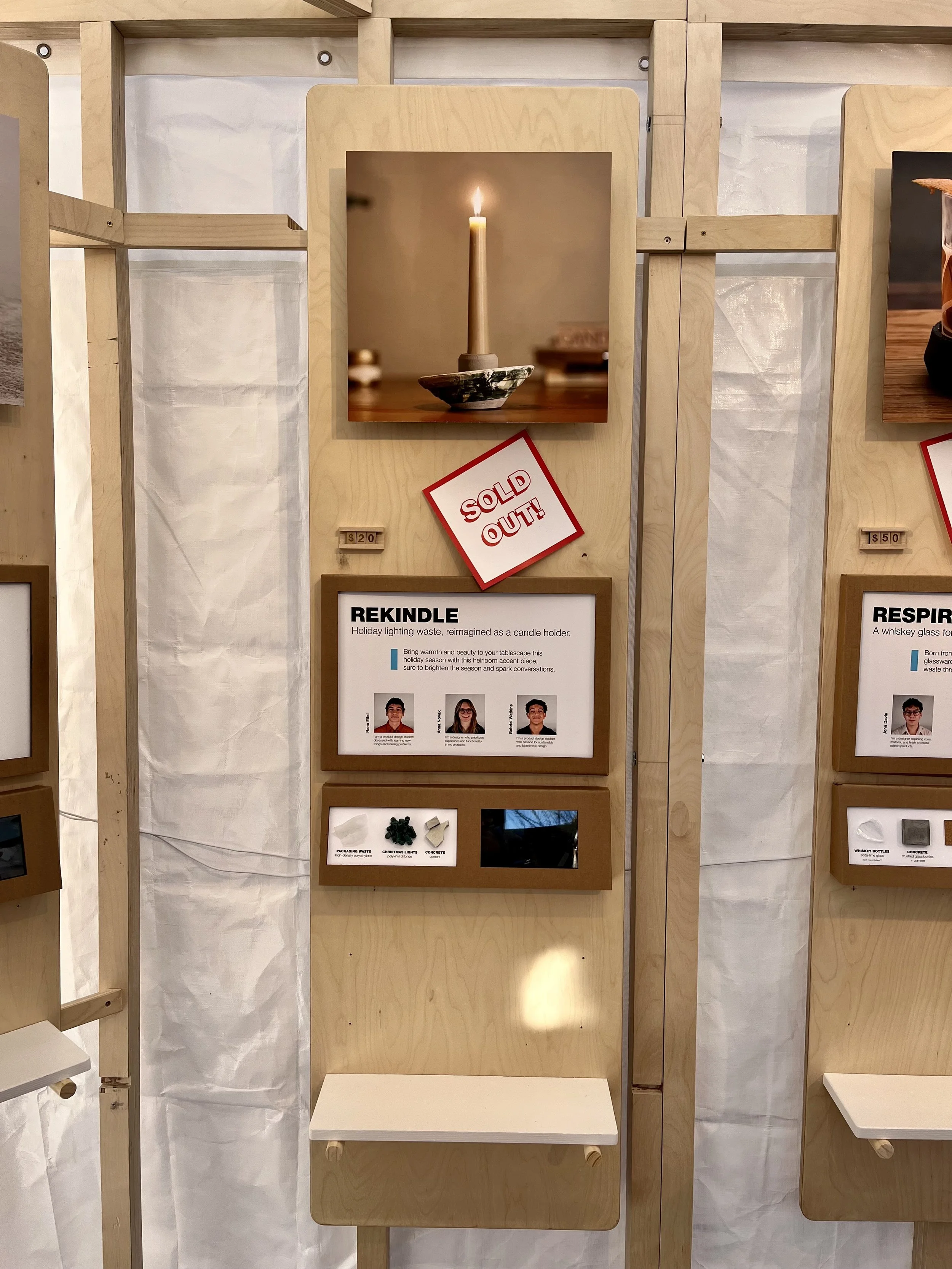

ReKindle

What is Rekindle?

ReKindle is an elegant holiday luminaire crafted from recycled Christmas lights and post-consumer plastics, including milk jugs, water jugs, cosmetic bottles, detergent containers, and other everyday packaging. Designed to elevate your space, this sculptural candlestick holder is made from discarded materials into a refined, meaningful centerpiece for your home. Thoughtfully designed and sustainably made, ReKindle brings new life and a warm, seasonal glow from materials that were once waste.

During the holiday season waste goes up about 25% from Thanksgiving to New Years, which is about 1 million extra tons of garbage weekly, so we as team holiday wanted to use some of this waste while also commenting on the immense waste we as humans create in general, and especially the increase during the holiday season.

Each piece is composed of two carefully crafted components: a durable rockite base that provides weight and stability, and a hand-formed recycled HDPE shell. These elements create a candle base that blends artisanal craftsmanship with environmentally conscious design where no two units are the same, providing each with there own uniqueness.

ReKindle is a third year project made for the University of Colorado Boulder’s Product Design Studio called EPOP.

What is it?

Picture Courtesy of Hannah Howell - CU Boulder CMDI

Epop is…

EPOP Shop is a product design studio offered by the University of Colorado Boulder’s Environmental Design Program. EPOP Shop is hosted annually in the fall, and about 39 students in groups of 3 take the whole semester to make one product per group, with a shop team. These products are required to be made of at least 50% diverted materials, designed, manufactured, and sold by the students.

EPOP shop covers a range of market groups, every group coming up with an original and unique product for their target market. All materials, designs, and methods are found or created by the students, and they sell their products once a year for a limited edition sale at the FireFly Market in Boulder, Colorado.

Time Lapse Video Courtesy of Hannah Howell - CU Boulder CMDI

The Shop Itself

In addition to the products in EPOP Shop, the shop itself was also built by students, with the guidance and help of the studio teachers, Jared Arp and Melissa Felderman. The shop itself is entirely modular, so it can be easily taken down, transported, and put back together again. The entire shop follows this format, being able to easily set it up at the FireFly HandMade Market.

The shop was originally built by one of the first studios to do EPOP Shop, and every year there is a shop team of 3 people that take on their own projects within the shop as well as the maintenance and advancements within the shop, including setup.

Picture Courtesy of Hannah Howell - CU Boulder CMDI

Meet Rekindle’s Designers

Anna Novak

I’m a designer who prioritizes experience and functionality in my products.

I am a product design student obsessed with learning new things and solving problems.

Gabriel Watkins

I’m a product design student with a passion for sustainable and biomimetic design.

Rana Eitel

Materiality

Rockite

HDPE Christmas Lights

HDPE Recycled Packaging

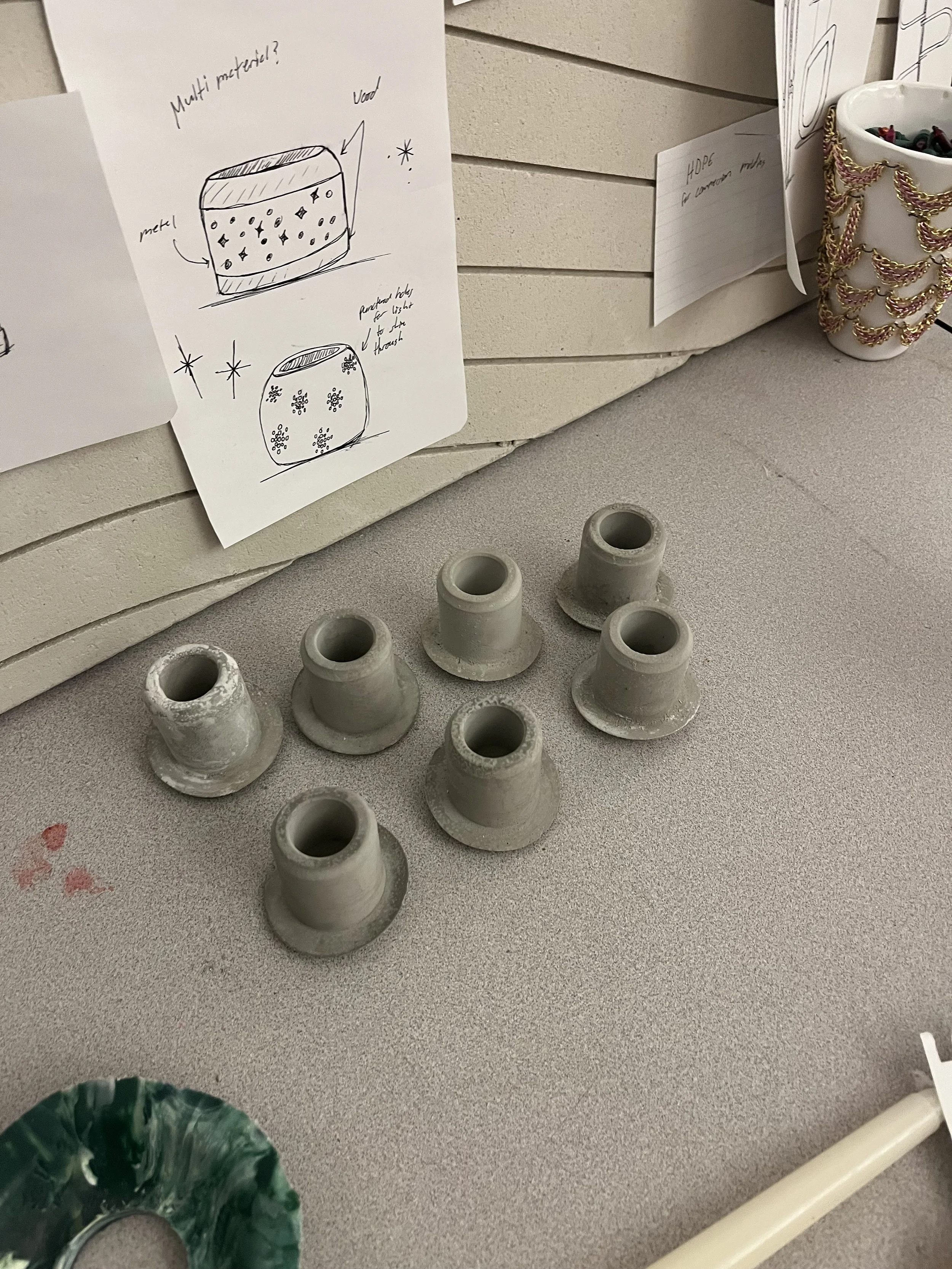

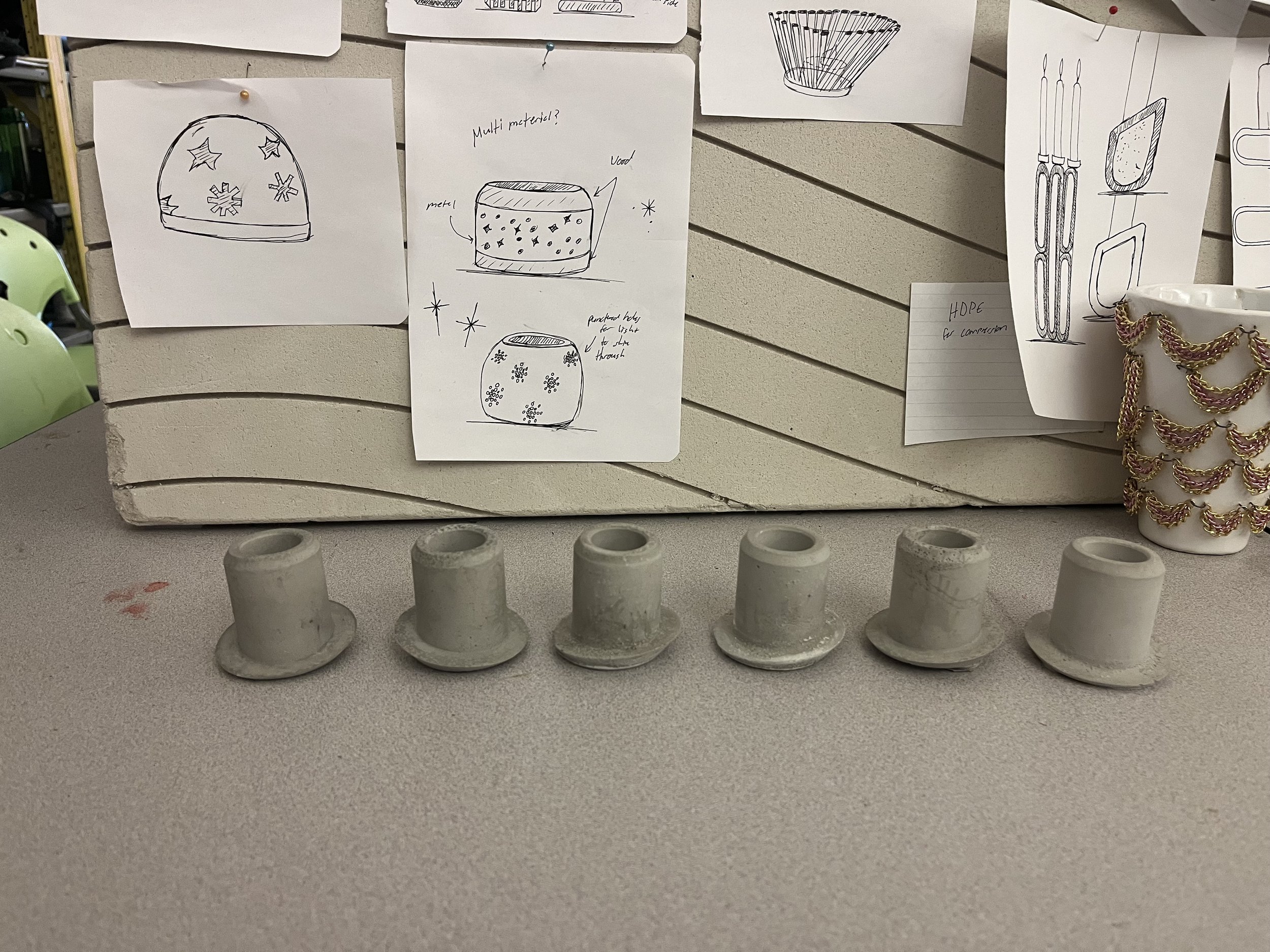

Process - prototyping

Making 3D models was a big part of our form exploration, being able to actually seeing what was possible for this project. This process was a combination of 3D prints, experimentation with aluminum casting, light throwing, metal and wood working.

Process - 3d Modeling

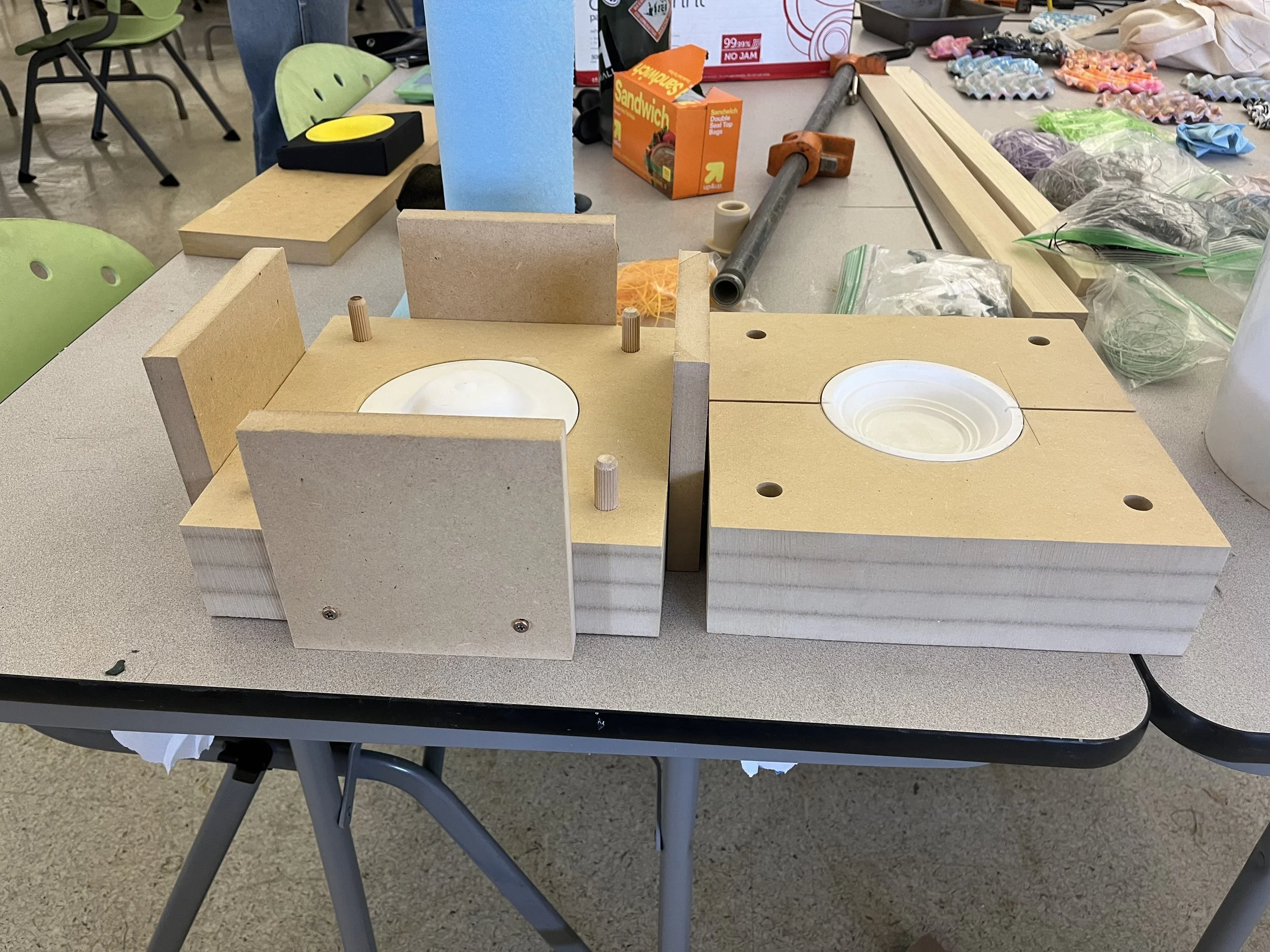

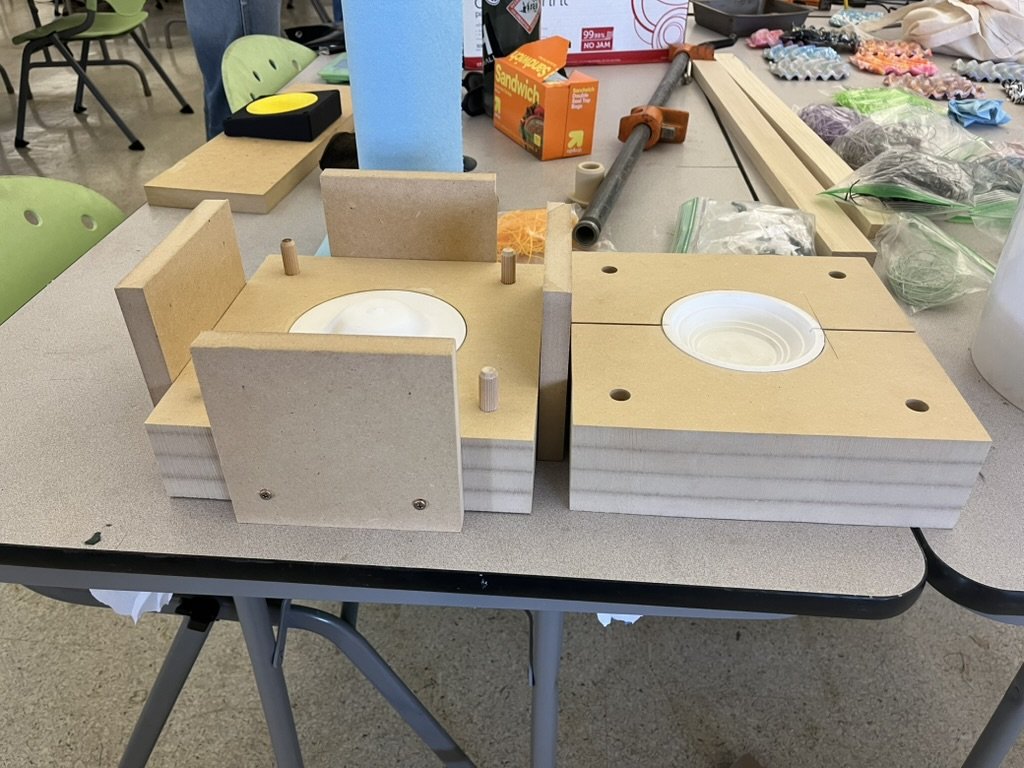

After deciding on both material and the basic form of our product we utilized 3D modeling software Rhino to continue with the specifics of our product as well as to prepare for the mold making.

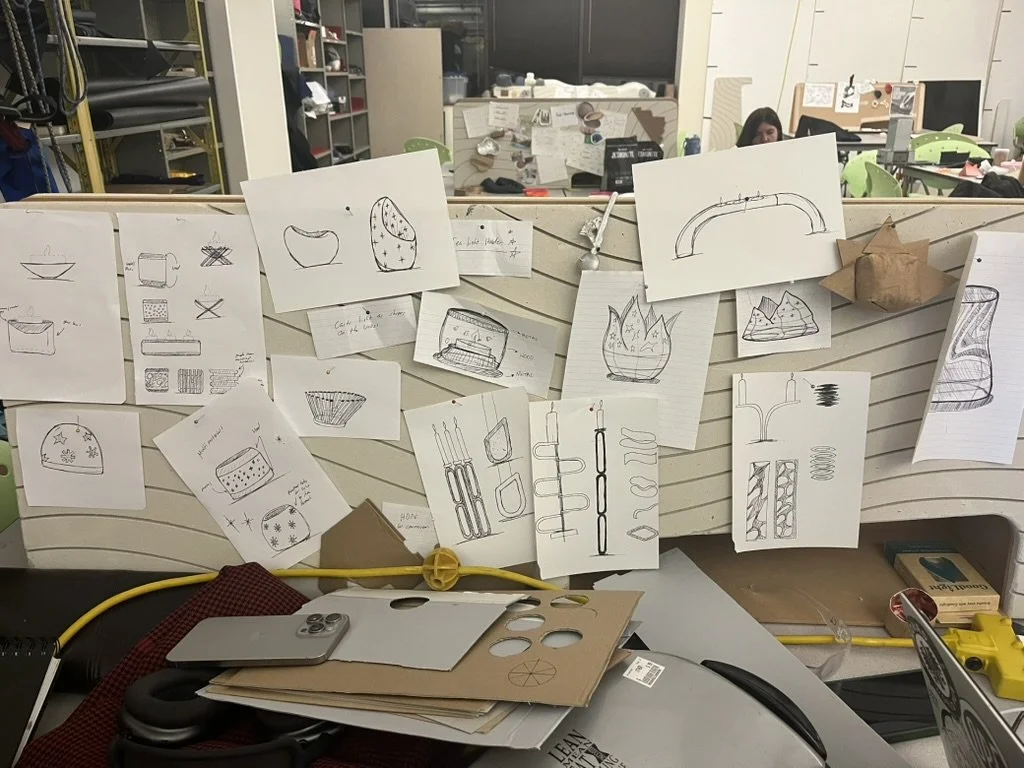

Process - Sketching

Sketching was one of the biggest parts of our design process throughout this experience, but particularly in the early stages, from sketching to figure out ideas, to sketching to get more iterations, and to sketching to find commonalities in our group.

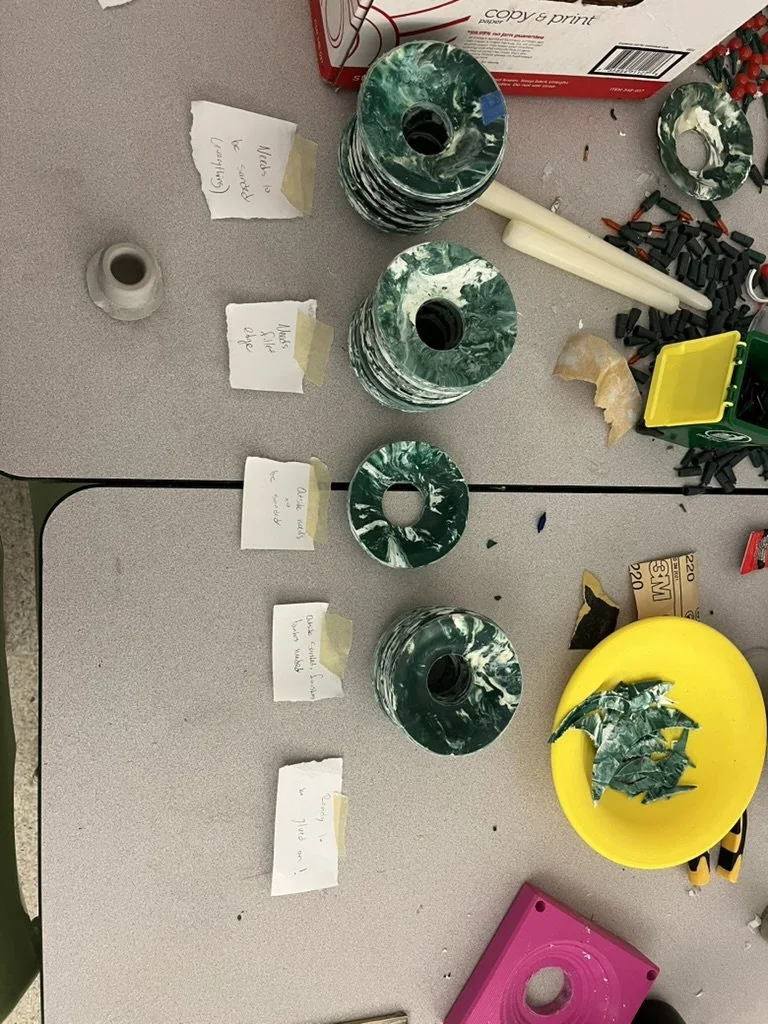

Process - Materiality Tests

Another huge component of the design process was the materiality tests we conducted. This ranged from testing which kind of plastic to melt, eventually landing on melted HDPE, and the materials themselves to test ratios, melting temperatures, heating, and cooling times.

How Rekindle is Made

1

Make the Rockite base, first mixing the rockite, spraying your mold release spray, then pouring it into the silicone mold, and finally getting the air bubbles out through vibrations under the mold.

2

Wait for the rockite to cure, for about 20-30 minutes, then carefully remove it from the mold.

3

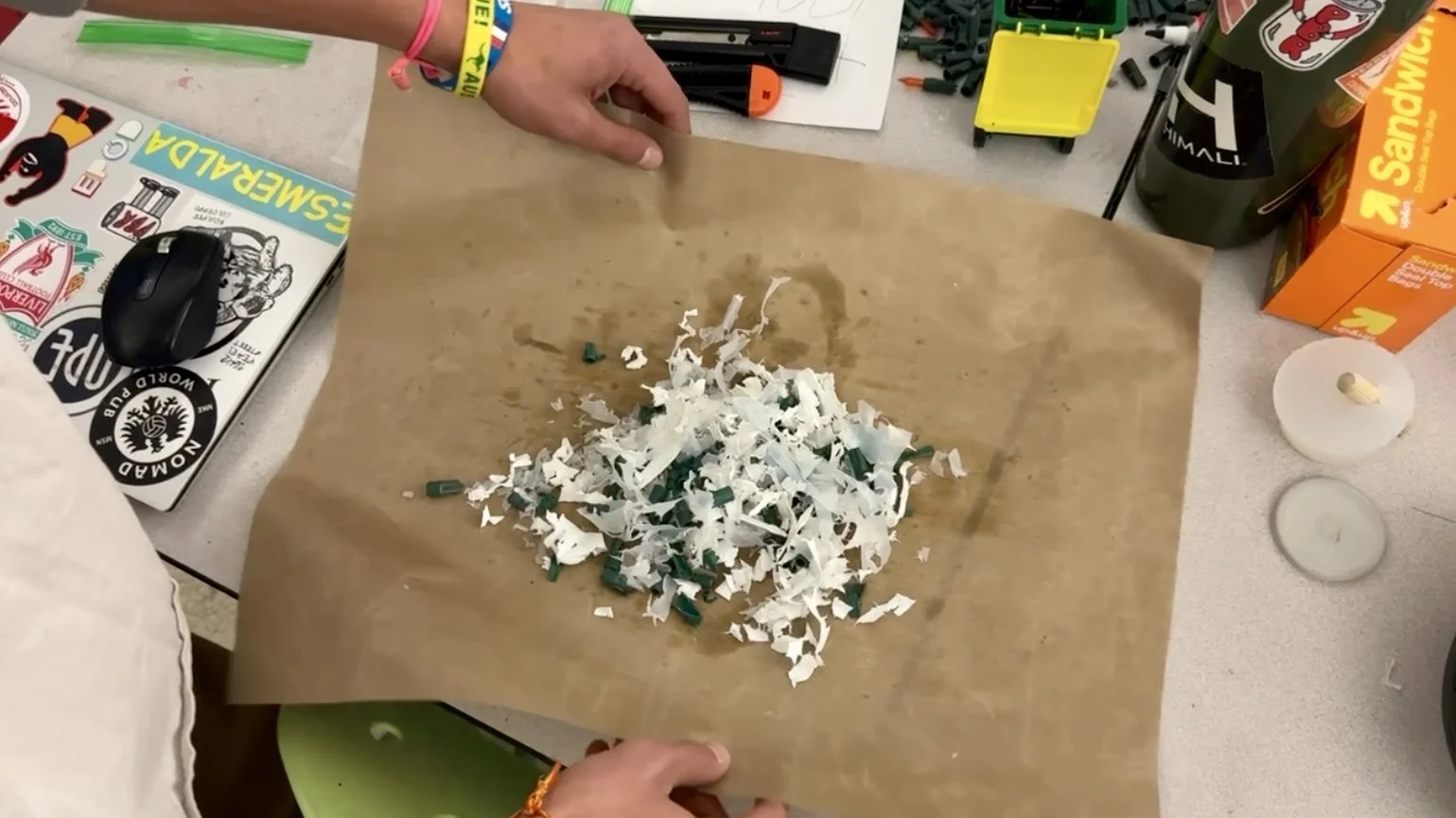

Harvest plastic for the shell by removing the bulbs, wiring, and fuses from Christmas-light sockets, then cutting and grinding the white and translucent HDPE plastic.

4

Throw the mix of plastic in the grill and wait about 10-15 minutes, kneading the plastic throughout this process.

5

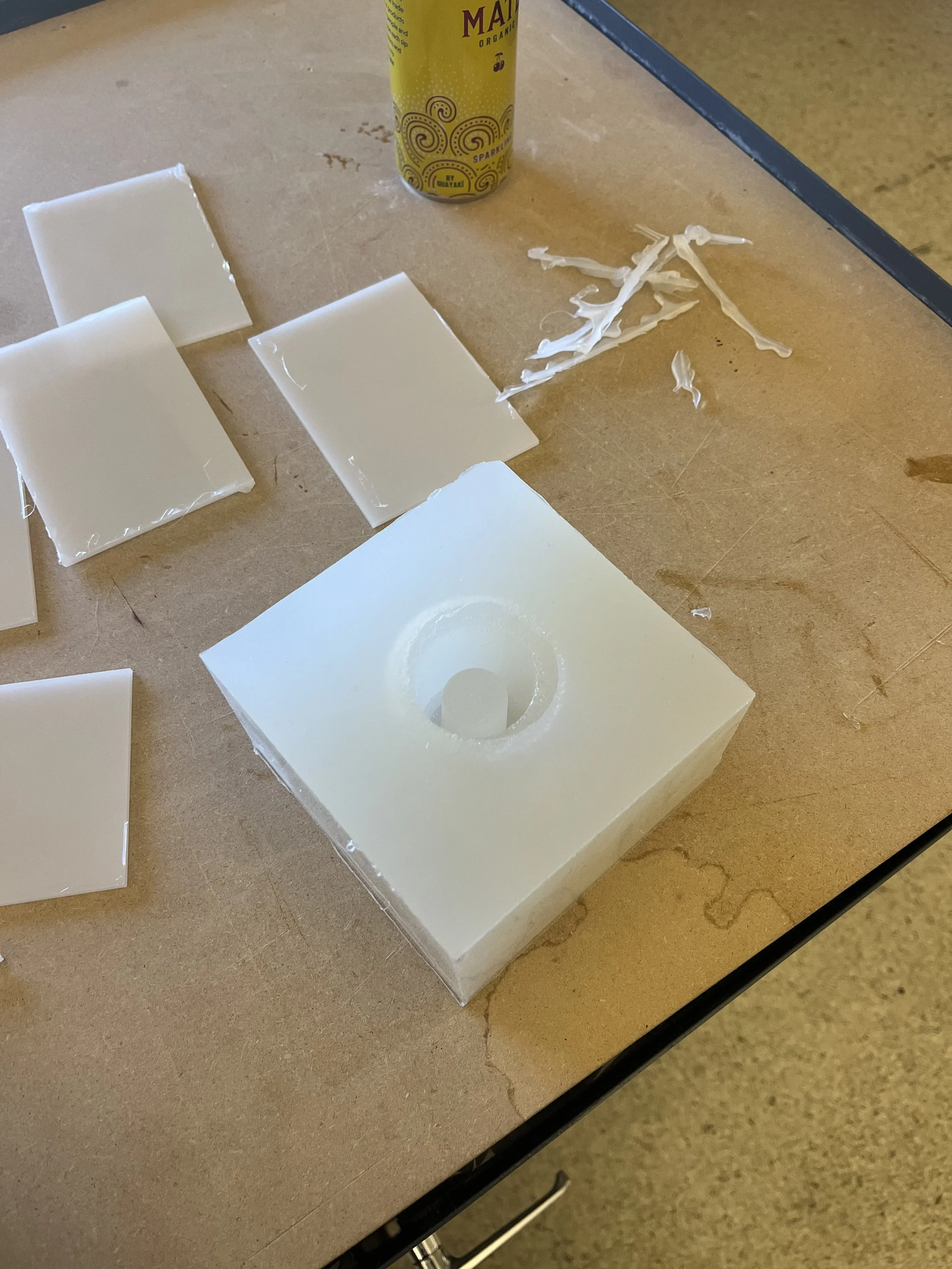

Once the plastic is melted and ready to be molded, get the 3D mold and very quickly transfer the hot plastic into the center of the mold, then closing the mold and transferring it to the hydraulic jack to put pressure and mold the shell. Leave for about 10 minutes, or until the plastic cools down.

7

Laser engrave and cut the cork base, and put the cork pad on the bottom for branding and protection.

6

8

Take out the plastic from the mold and get ready to clean it up. First by cutting off the excess plastic around the shell with a band saw, then drilling a hole at an angle with the drill press. From there we sand both the interior and exterior of the shell and get ready to put the rockite base and shell together.

ReKindle!

Process Video

Harvesting the plastic from the broken Christmas Lights

Harvesting the plastic from old packaging materials

Taking the ready to go melted plastic out, transferring it to the mold, and pressing it with the hydraulic jack.

In action - Video gallery

Kneeding the melted plastic to get the marbled effect

Taking the cooled plastic out of the jack, and then out of the mold.

Taking the dried rockite base out of the silicone mold

Gallery #1 - Photos by Hannah Howell of CU Boulder’s CMDI

Gallery #2 - Photos by Anna Novak